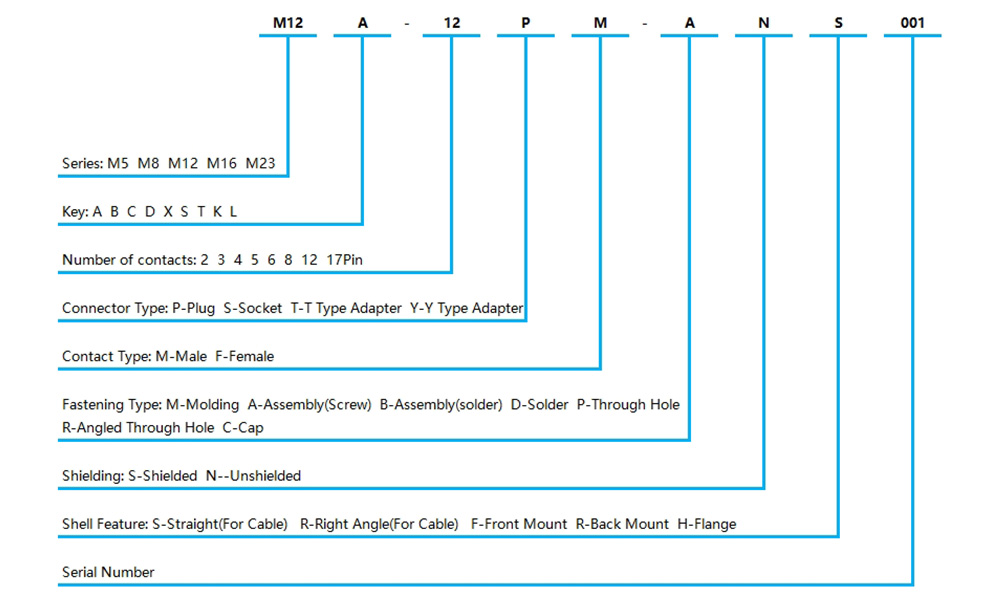

Part Number :

| M12A-2PM-AS-R001 | Male M12 A 2 pin Right Angle Metal Shell Shielded |

| M12A-3PM-AS-R001 | Male M12 A 3 pin Right Angle Metal Shell Shielded |

| M12A-4PM-AS-R001 | Male M12 A 4 pin Right Angle Metal Shell Shielded |

| M12A-5PM-AS-R001 | Male M12 A 5 pin Right Angle Metal Shell Shielded |

| M12A-6PM-AS-R001 | Male M12 A 6 pin Right Angle Metal Shell Shielded |

| M12A-8PM-AS-R001 | Male M12 A 8 pin Right Angle Metal Shell Shielded |

| M12A-12PM-AS-R001 | Male M12 A 12 pin Right Angle Metal Shell Shielded |

| M12A-17PM-AS-R001 | Male M12 A 17 pin Right Angle Metal Shell Shielded |

| M12D-4PM-AS-R001 | Male M12 D 4 pin Right Angle Metal Shell Shielded |

| M12X-8PM-AS-R001 | Male M12 X 8 pin Right Angle Metal Shell Shielded |

M12 Field Wireable Connectors are a special type of M12 connector, the main advantage of which is that they allow the user to wire cables in the field without having to rely on pre-fabricated connectors and cable assemblies. This saves time and costs and provides greater flexibility, especially where field adjustments or wiring changes are required.

Connector Orientation

The choice of right angle or straight M12 Field Wireable Connector depends on the specific application requirements and installation environment. If space is limited or wiring along the surface of the machine or equipment is required, right angle connectors are the better choice. If a direct connection or easy installation is required, a straight connector is more suitable.

Straight

Right Angle

Connector Shell

Shell selection for M12 connectors can be evaluated based on specific application requirements and environmental conditions. If higher durability, interference immunity, or protection ratings are required, metal shells are a better choice. Whereas, in general industrial environments or indoor applications, plastic shell connectors can provide affordable and reliable performance.

Plastic Shell

Metal Shell

Applications

M12 connectors have a wide range of applications in various fields, including industrial automation, machinery and equipment, robotics, process control, and sensor and actuator connections.