Renhotec Marine Series Connectors

Renhotec Marine Series Connectors are designed with the special requirements of the marine environment in mind, often utilizing corrosion-resistant materials, watertight sealing designs, and reliable connection technology. They undergo rigorous testing and certification to ensure their reliability and safety in the marine environment. With the increase in marine engineering and marine resource development, the demand for marine connectors will continue to grow and play an important role in the development of the marine field.

Underwater Series

We produce a wide range of underwater connectors compatible with Seaconn and Subconn alternatives to meet the needs of different applications. We provide signal, coaxial, high voltage, high current, optical fiber, fluid, through the wall, wet plug, underwater live plug, oil, field installation and other types of watertight connectors, from 1 to 203 core, the maximum working water depth of 14000 meters.

By testing our products to the highest standards, we help you carefully select the right level of environmental and sealing solution that matches the specific environment and conditions in which your equipment will operate.

Renhotec underwater connectors have the following features:

- Excellent waterproof performance, can effectively prevent moisture, humidity or other liquids from penetrating into the connector, to protect the electrical signals and electrical components in the connector, to ensure the reliability of the system.

- Made of corrosion-resistant materials such as stainless steel, nylon and silicone, it can resist corrosion and oxidation in humid environments, thus extending the service life of the connector.

- High strength, drop resistance and pressure resistance to withstand physical compression, shock and vibration in a variety of harsh environments.

- Simple design, easy to install, usually with plug-and-play connections for easy maintenance and replacement.

Fiber Optic Series

Fiber Optic Underwater Connector OPT-A2E2-DSP Plug and Socket

Fiber Optic Series

Fiber Optic Underwater Connector OPT-B-DSP 1 Pin Plug and Socket

Coaxial Series

Coaxial Series

Coaxial Series

Coaxial Series

Flat Series

Flat Series

Flat Series

Flat Series

RMG Series

RMG Series

RMG Series

Application examples of high-performance underwater connectors

Renhotec’s underwater connectivity solutions withstand the rigors of harsh environments.

Unmanned Underwater Vehicles (UUVs)

Unmanned Underwater Vehicles serve various functions, including ocean exploration, reconnaissance, and environmental monitoring. A critical component of UUVs is the underwater connectors, which facilitate the transmission of power, control signals, and data between the vehicle and its systems or external equipment.

Equipped with diverse sensors and measuring instruments, UUVs collect and transmit data about their environment. Underwater connectors enable real-time data transmission to the surface or other external devices for ongoing monitoring and analysis.

Diving Equipment

In diving equipment, underwater connectors play a vital role in linking the diver’s communication equipment, lighting systems and other auxiliary equipment to ensure reliable operation and data transmission underwater. Even in high-pressure and wet environments, these connectors are essential for maintaining communication between divers and surface teams. Underwater connectors support effective and seamless underwater exploration.

Marine Scientific Research Equipment

Marine scientific research equipment needs to operate in harsh underwater environments for long periods of time, such as deep-sea probes and undersea observatories. Underwater connectors ensure the safe and stable transmission of data and power to these devices. These instruments often include multiple sensors and devices. Underwater connectors enable reliable connections between these devices.

Ships and Offshore Platforms

Underwater connectors on ships and offshore platforms transfer power and signals between navigation, communication, and monitoring systems, ensuring safe operation in wet environments. Ships use waterproof connectors to link GPS, radar, and sonar equipment for accurate navigation information. Offshore platforms rely on these connectors to maintain reliable connections among numerous sensors and monitoring systems, facilitating safe operations and timely maintenance.

NMEA 2000 Series

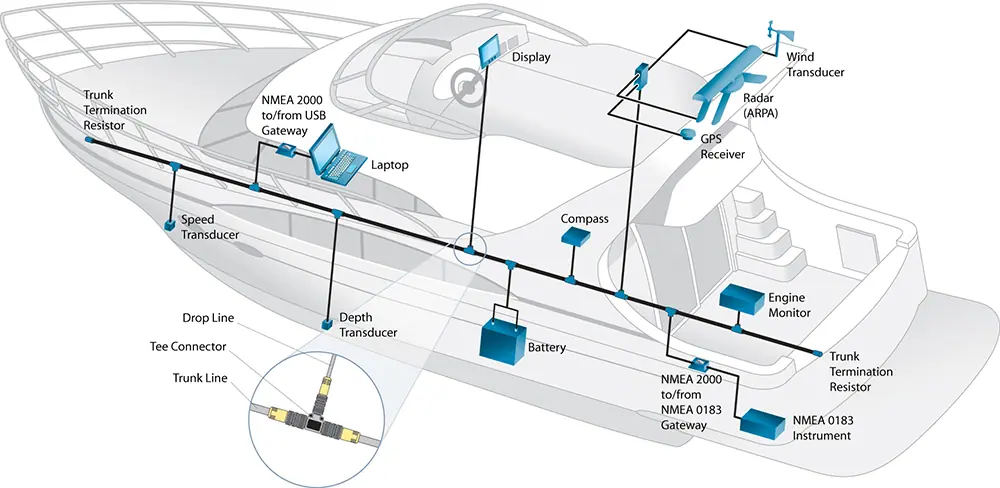

NMEA 2000 is an important standard for seamless communication between shipboard electronic equipment and plays a key role in enhancing the interoperability and integration of equipment on board. The National Marine Electronics Association (NMEA) developed the standard to meet the growing need for efficiently sharing data between various types of marine instruments and systems.

In the past, different manufacturers have tended to use proprietary protocols, which has led to compatibility issues and made it difficult for crews to integrate multiple pieces of equipment together.NMEA 2000 solves these problems by providing a unified method of communication that allows a wide range of equipment, from navigational aids and radar systems, to engine monitoring instruments and a wide range of sensors, to work in harmony.

Key features of the NMEA 2000

CAN bus technology: NMEA 2000 is based on Controller Area Network (CAN) technology, an efficient and reliable serial communications protocol that supports the connection and communication of multiple devices.

Plug and Play: Devices can be quickly connected to each other using standard connections, simplifying the installation and configuration process.

Comprehensive Data Sharing: Allows devices from different manufacturers to share and exchange data, improving system flexibility and scalability.

Network structure: Supports star, bus or ring network structure, which can be flexibly set up according to the specific ship configuration.

Standardisation: A range of standard data message formats are provided to ensure that the same data can be understood and used between different devices.

Typically used on all types of watercraft, such as yachts, fishing boats and commercial vessels, NMEA 2000 provides a stable communications solution that makes on-board navigation and monitoring more efficient and convenient.

The Renhotec NMEA 2000 connectors feature a standardized physical connection interface to ensure interconnectivity and communication with other manufacturers’ equipment, as well as good reliability and waterproofing for the challenges of the marine environment. They are designed and tested to ensure reliable connections and data transmission in harsh conditions such as humidity, salt spray and vibration.

Renhotec NMEA 2000 series main products:

- Trunk and branch cables: connects NMEA 2000 devices and creates networks.

- T-connectors: connect devices to the backbone cable.

- Terminating resistors: installed at both ends of the network to ensure signal integrity

NMEA 2000 Terminator Resistor

NMEA 2000 Mini-C 7/8″ 5Pin Female Termination Resistor For Marine & Oceanic System

NMEA 2000 Terminator Resistor

NMEA 2000 Mini-C 7/8″ 5Pin Male Termination Resistor For Marine & Oceanic System

Application examples of high-performance NMEA 2000 Connectors

Renhotec NMEA 2000 connectors seamlessly interconnect and communicate with equipment from different manufacturers.

NMEA 2000 Trunk and Branch Cables

On a ship, the backbone cable may run from the cockpit to the stern, connecting various devices such as GPS, autopilot and engine sensors. Branch cables connect to each device to form a complete network system.

Applications

The backbone cable acts as the core of the network, connecting all NMEA 2000 devices together and providing a path for data transmission. Branch cables are used to connect devices to the backbone cable, allowing them to access the network from different locations. They help to create the complete NMEA 2000 network structure and ensure that devices are able to communicate effectively across the network.

NMEA 2000 T Connectors

In a complex ship navigation system, you can connect new sensors, such as wind speed sensors, to the backbone cable using T-connectors without needing to rewire or interrupt connections to other devices.

Applications

Used to connect individual devices or groups of devices to the backbone cable to form branch points. This type of connection makes network expansion and device additions more flexible and convenient. It allows new devices to be added anywhere on the backbone cable without affecting the rest of the network.

NMEA 2000 Termination Resistors

In a ship’s NMEA 2000 network, technicians typically install terminating resistors at both ends of the trunk cable (i.e., at the beginning and end of the network) to ensure that all devices can reliably receive and send data.

Appliances

Technicians install terminating resistors at both ends of a network to match the impedance of the cable, prevent signal reflection and interference, and ensure the stability and reliability of data transmission. They help maintain the electrical characteristics of the network and avoid data transmission errors caused by signal distortion or reflection.