In modern industrial automation, connectors play a crucial role, especially in complex environments where reliable and efficient solutions are essential for stable equipment operation. The M12 circular connector stands out for its excellent protection, vibration resistance, easy installation, and flexible coding design, making it an indispensable component in industrial automation. As a key link between devices, the M12 connector connects components like sensors, actuators, and machine vision systems, ensuring stable transmission of data, power, and signals in harsh environments.

Advantages of M12 Connectors

One of the main benefits of M12 circular connectors is their strong protection. With an IP67 rating, they resist water, dust, and moisture, maintaining high performance in extreme environments. This protection makes M12 connectors a critical component in industries like automation, transportation, energy, and chemicals.

Additionally, M12 connectors excel in vibration resistance. In environments with high vibrations or shocks, these connectors continue to transmit signals and power stably. This prevents issues like loose connections or signal interference caused by vibrations. Therefore, industries such as precision equipment, automated production lines, robotic systems, and sensor networks rely on M12 connectors for their reliable and robust connections.

Coding Design — Preventing Incorrect Connections

Another standout feature of M12 circular connectors is their coding design, which prevents accidental misconnection between different signal types. The coding system identifies the electrical characteristics and application scenarios of connectors, ensuring they only pair with compatible sockets or plugs. This design prevents mispairing, reducing the risk of equipment damage, and significantly increases safety and reliability in industrial equipment.

The Role of Coding Keyways:

Prevents Incorrect Pairing and Misconnection: M12 connectors feature coding that ensures each connector pairs only with its intended socket or plug, solving the problem of mispairing or incorrect insertion. This design helps avoid damage and operational errors.

Improves Safety: As equipment becomes more complex, safety becomes a critical requirement. The coding system minimizes human error, ensuring stable long-term operation and reducing the risks of malfunction from improper connections.

Ensures Proper Signal Transmission: Coding guarantees correct signal distribution, whether for power, data, or control signals. This prevents issues like signal loss or interference.

M12 Connector Coding Explained

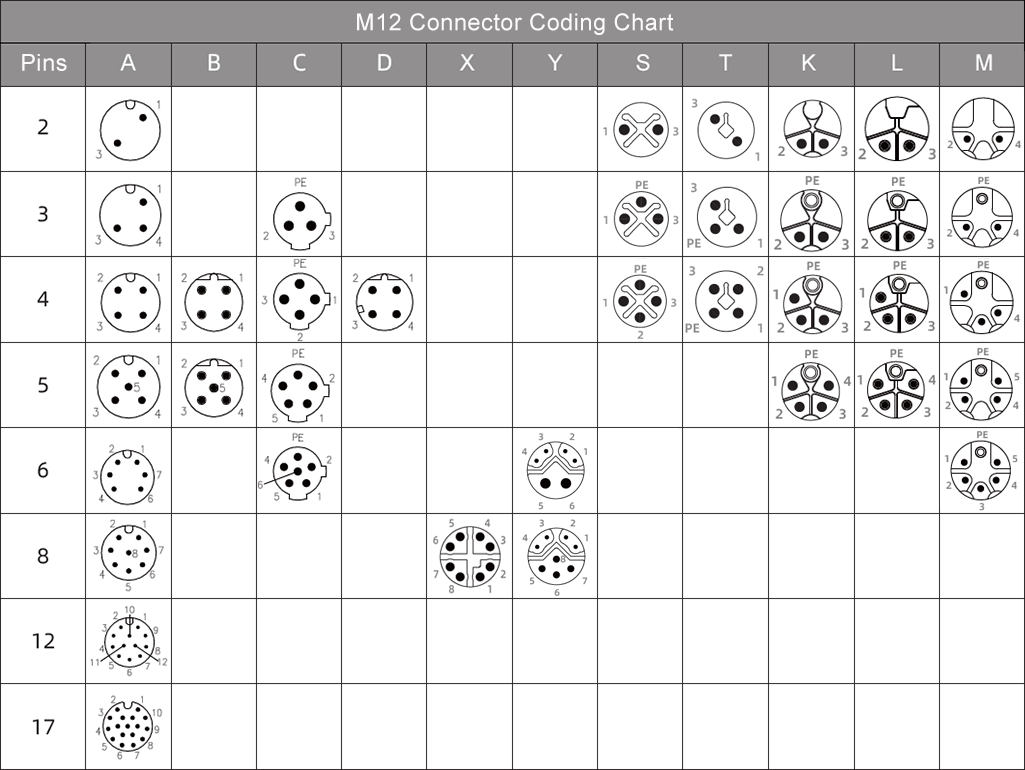

M12 circular connectors use letter codes to indicate electrical properties, application types, and supported transmission speeds. These codes help users choose the right connector based on their needs.

A Code:

A code is common for general-purpose sensors, actuators, and IO-Link devices. Connectors can have 2 to 17 pins, supporting a variety of connection needs. A code connectors support 1Gbps Ethernet signal transmission and are also suitable for DC power connections. Their versatility makes A code the most widely used in industrial automation.

B Code:

B code is designed for control systems and fieldbus communication protocols, such as Profibus and Interbus. These connectors typically feature 5 pins and meet specific communication requirements in industrial automation.

D Code:

D code connectors support 100Mbit Ethernet connections and generally use 4 pins. They’re ideal for medium-speed data transmission, such as in PROFINET networks, railway CCTV control systems, and devices like servo motors and encoders.

X Code:

X code connectors are designed for high-speed data transmission, supporting up to 10Gbps Ethernet connections. These connectors typically use 8 pins and serve high-speed industrial networks, video surveillance, and industrial communication systems. As bandwidth demands increase, X code is expected to lead the future of high-speed industrial Ethernet.

K Code:

K code connectors meet specific AC power requirements, with a unique 5-pin structure that transmits control, power, and status signals. They offer small size, high current, high voltage, and IP67/IP68 protection, making them perfect for tough environments with high temperature, humidity, and vibration.

L Code:

L code connectors are used for high-power electrical connections in industrial equipment, such as PROFINET systems and power supply units. They offer small size, high current, and an IP67/IP68 protection rating, providing precise, flexible connections in harsh industrial environments.

S Code:

S code connectors are specifically designed for AC power connections, offering good shielding and high protection ratings. These connectors are ideal for automation equipment that requires reliable AC power connections, and they replace C code connectors in power systems.

T Code:

T code connectors are used for DC power connections. They offer high reliability, IP67 or higher waterproof performance, and are widely used in industrial automation devices requiring stable DC power. These connectors often replace A code connectors in DC power applications, offering better stability and reliability.

The Role of M12 Circular Connector Coding

Preventing Mismatched Pairing:

The coding design ensures that connectors only pair with compatible sockets or plugs. This eliminates the risk of incorrect connections, preventing equipment failure or malfunction and enhancing overall safety.

Providing Shielding Protection:

Many M12 connectors with specific codes come with shielding to reduce electromagnetic (EMI) and radio-frequency interference (RFI). This protection ensures stable and reliable data transmission, particularly in environments where signal integrity is critical.

Identifying Electrical Characteristics:

The coding system clearly indicates a connector’s electrical properties, such as Ethernet speeds, power types, and transmission capabilities. This helps users make informed decisions when selecting connectors for their specific applications.

As industrial automation continues to evolve, the demand for high-performance connectors is growing. M12 connectors, with their high protection ratings, vibration resistance, and flexible coding options, are becoming integral in modern industrial systems.

The need for M12 connectors will likely increase in industries requiring high-speed Ethernet and smart manufacturing. As data transmission rates and network bandwidths continue to grow, M12 connectors will evolve to meet these higher demands. X code connectors, in particular, are expected to play a major role in the future of high-speed industrial Ethernet, while other coding types will continue to improve to meet various industrial requirements.

Renhotec is a leading manufacturer of circular connectors and offers a wide range of M12 circular connectors with different coding options. These solutions ensure reliable and efficient signal, power and data transmission for your equipment in a variety of industrial environments. Whether you work on automated production lines, robotic control systems, sensor networks, or in industries such as railroads, automotive and energy, our M12 connectors provide a stable connection to keep your equipment running smoothly.